Research & developement

Analytical Method Development (AMD) is crucial in various fields, particularly in pharmaceuticals, food safety, environmental analysis, and chemical manufacturing. Here’s why it’s so important:

- Accuracy and Precision: AMD ensures that analytical methods used for testing are reliable, accurate, and precise, which is essential for obtaining consistent results. This is vital for making informed decisions based on test data.

- Regulatory Compliance: In industries like pharmaceuticals, the development of robust analytical methods is necessary to meet regulatory requirements set by authorities like the FDA, EMA, or EPA. Properly validated methods help ensure that products are safe and effective.

- Quality Control: By developing and validating analytical methods, companies can maintain high-quality standards for their products. This ensures that batches of drugs, food products, or chemicals consistently meet safety and quality standards.

- Cost-Effectiveness: Well-developed methods improve efficiency by reducing the need for repeated tests or troubleshooting. This helps minimize waste, time, and resources.

- Optimization of Processes: Analytical methods are key to monitoring production processes, helping identify problems early and allowing for process optimization. This can lead to better yields, lower costs, and enhanced product quality.

- Troubleshooting: When issues arise in production or testing, having a solid analytical method helps quickly pinpoint the root causes, whether they are due to raw materials, equipment, or environmental factors.

- Innovation and Research: In research and development, developing new analytical methods is crucial for studying novel compounds, formulations, or materials, allowing for new discoveries or improvements in existing products.

Ultimately, AMD is a foundational part of ensuring that products are safe, effective, and of high quality, while also enabling innovation and efficiency.

Analytical method validation and verification are crucial aspects in ensuring the reliability, accuracy, and precision of results produced by analytical techniques. They are fundamental in industries such as pharmaceuticals, biotechnology, food safety, and environmental testing, where decisions based on data can impact public health and safety. Here’s why both processes are important:

- Analytical Method Validation

Validation refers to the process of confirming that an analytical method is suitable for its intended purpose. It ensures that the method performs as required, delivering results that are both accurate and reproducible.

Importance of Validation:

- Reliability of Results: Validation demonstrates that the method provides consistent, reliable results under various conditions. This is crucial when the accuracy of data directly impacts product quality, safety, or regulatory compliance.

- Regulatory Compliance: Regulatory agencies (e.g., FDA, EMA) often require validated methods for new drugs, medical devices, and other products. Validation ensures compliance with regulations and avoids potential legal or financial penalties.

- Scientific Integrity: Validating a method ensures that the data produced is scientifically sound, fostering credibility in research or clinical trials.

- Risk Reduction: Proper validation helps in identifying potential sources of error or inconsistency in results, reducing the risk of incorrect conclusions that could harm public safety or lead to costly product failures.

- Quality Assurance: It ensures that the method is robust and suitable for the intended use, providing confidence that the quality of a product or process is consistently maintained.

- Analytical Method Verification

Verification, on the other hand, is the process of confirming that an analytical method, once validated, continues to perform as intended in a specific laboratory or environment. This step is often done when the method is transferred or applied in a new setting or laboratory.

Importance of Verification:

- Consistency Across Laboratories: Verification ensures that a method previously validated in one laboratory can be used effectively in another without compromising results.

- Transferability: When methods are transferred to different labs or teams, verification helps confirm that the method will yield the same performance (accuracy, precision, etc.) as in the original setting.

- Adaptation to New Conditions: Methods might need to be verified if the environmental conditions, instruments, or reagents change. It ensures the method remains accurate and reliable in the new context.

- Efficiency and Cost-Effectiveness: Instead of re-validating a method in a new setting, verification ensures the existing validation still applies. It’s a more efficient process while still ensuring quality.

- Regulatory Confidence: In regulated environments, verification provides additional assurance to stakeholders, including regulatory agencies, that the method continues to perform according to the validated parameters.

Key Differences:

- Validation is a one-time process (unless the method or conditions change significantly).

- Verification is an ongoing or periodic process, ensuring the method still performs correctly under changing circumstances.

Conclusion

Both validation and verification are essential to maintaining the integrity of analytical processes. Validation establishes the method’s initial suitability for its purpose, while verification ensures that the method remains effective and accurate over time and across different environments. Together, they ensure that analytical results are trustworthy, reproducible, and meet regulatory standards, which is crucial in many fields, particularly in industries related to health and safety.

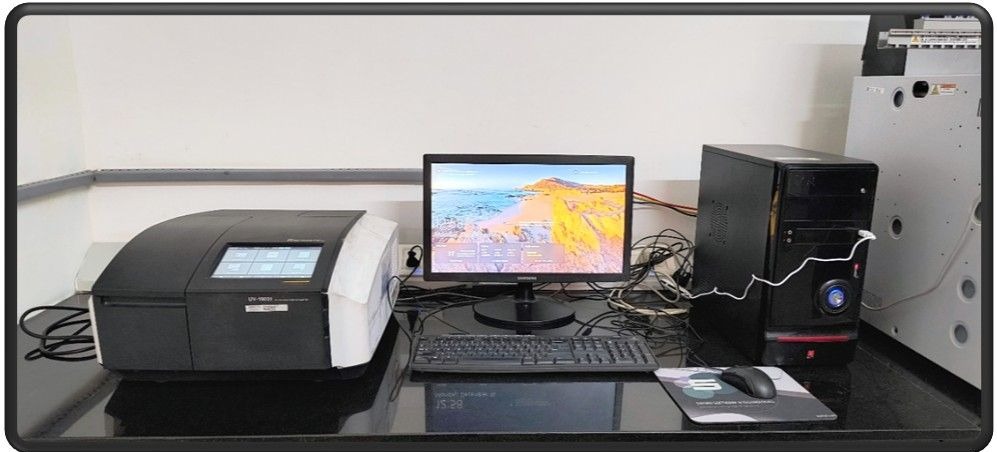

Our Facilities :

Tephra Biosciences, having the capability to develop methods across a range of techniques like Wet Chemical methods, GC (Gas Chromatography), HPLC (High-Performance Liquid Chromatography), and LC-MS/MS (Liquid Chromatography with Tandem Mass Spectrometry) is an excellent foundation for comprehensive analytical testing.

- Wet Chemical Methods: These are typically used for basic and traditional chemical analyses. Wet chemistry methods can involve titrations, precipitation, and colorimetric analysis, making them suitable for relatively straightforward or large-scale batch analyses, especially in the pharmaceutical or food industries. They are valuable for routine quality control checks.

- GC (Gas Chromatography): This method is commonly used for separating and analyzing volatile compounds. It’s ideal for detecting trace levels of volatile organic compounds (VOCs), essential oils, environmental pollutants, and other gases. It’s often employed in environmental testing, petrochemical analysis, and fragrance and flavor profiling.

- HPLC (High-Performance Liquid Chromatography): HPLC is versatile and is widely used for analyzing non-volatile, thermally unstable, or polar compounds. It’s an essential tool for food & agro-chemicals applications, especially for active ingredient quantification, impurity profiling, and stability testing. HPLC can be used for both routine analysis and method development for more complex mixtures.

- LC-MS/MS (Liquid Chromatography-Tandem Mass Spectrometry): LC-MS/MS combines the separation power of liquid chromatography with the sensitive and precise detection of mass spectrometry. It’s a powerful tool for complex sample matrices, trace analysis, and detecting low-abundance compounds. This technique is indispensable in pharmaceutical research, food and water, environmental testing, and clinical analysis, especially for target and non-target analysis.

Submit Your Query for Analytical Method Development, Validation and Verification: